What is layer thickness?

The importance of coating thickness measurement

As a truck or machinery manager, you are busy every day. The quality of the parts you use is essential for the smooth operation of your equipment. This also applies to the protective finish of these parts, especially since they are constantly exposed to aggressive external elements. Coating thickness measurement is a crucial test that assesses the quality of chromed surfaces, among other things. Curious about how this process works? Discover it here!

What is a coating thickness measurement?

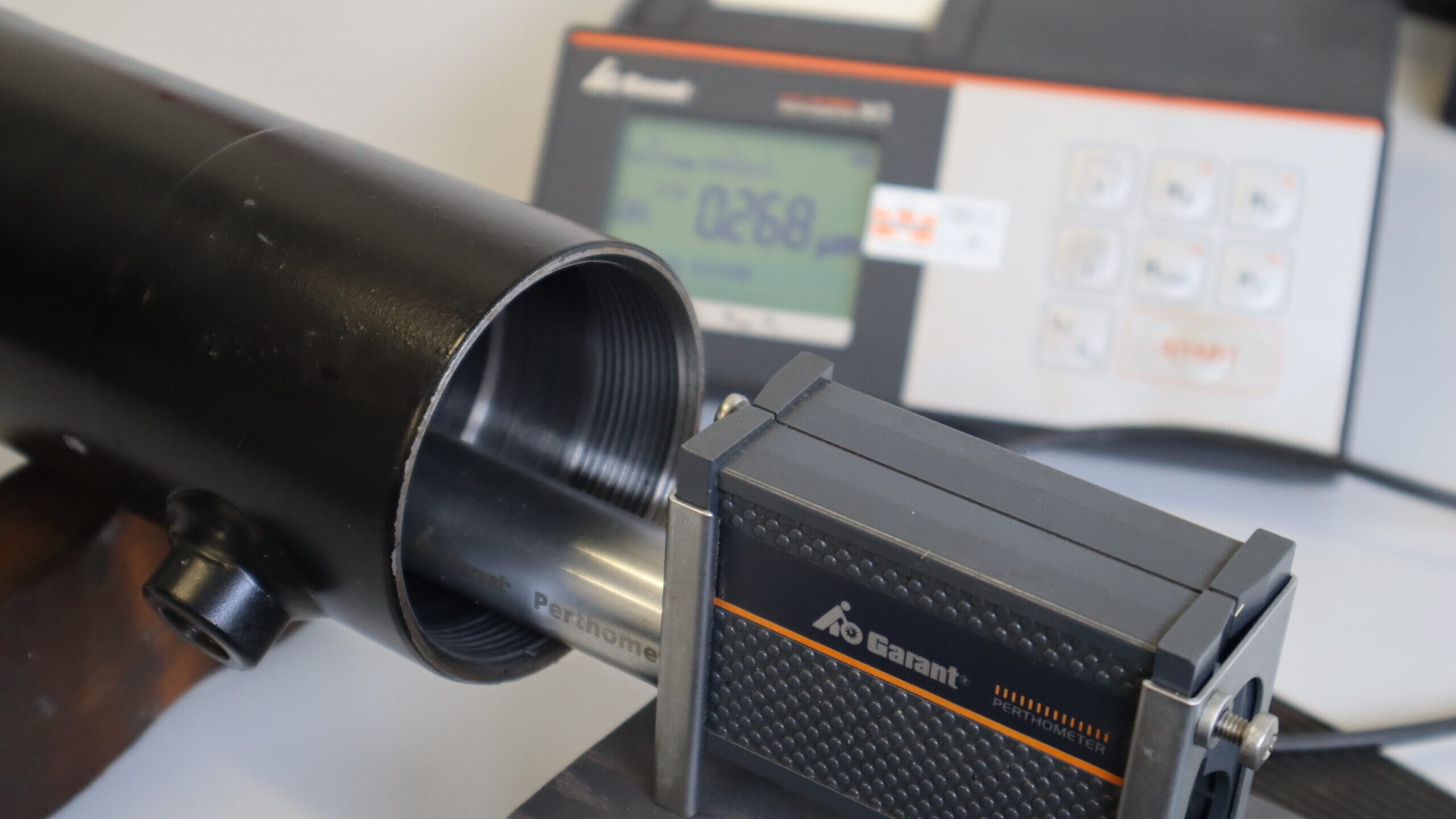

Chrome plays a crucial role in improving corrosion resistance, which is essential for the durability of metal parts. However, when corrosion resistance is insufficient, parts can quickly become damaged. The thickness of the chrome layer is an important indicator of the quality of the chromed surface. This layer thickness can be accurately measured using special devices designed for coating thickness measurements. These measurements analyze the thickness of paint, chrome layers, and coatings, contributing to quality control and material durability.

Coating thickness measurement in practice

A part can quickly become damaged when corrosion resistance is too low. Take, for example, the piston rod, a component that is constantly exposed to aggressive elements such as moisture, salt, and sand. If the piston rod is not properly protected, it can corrode repeatedly and eventually fail to function properly. It is crucial for piston rods to have a chrome layer with a minimum thickness. The coating thickness measurement determines whether this requirement is met.

Additionally, the coating of the cylinder housing is also assessed with a coating thickness measurement. This part is also exposed to changing weather conditions and must therefore be well protected against corrosion.

Related wiki's

Hardness measurement

A smooth workday begins with well-functioning equipment, which not only increases work satisfaction but also enhances efficiency. However, a malfunctioning foot control of a tail lift can cause a lot of frustration. Fortunately, this can easily be prevented through a simple test. In this text, you’ll discover how we avoid such annoyances and make your workday run more smoothly.

Roughness measurement

Did you know that the roughness of a surface, such as on tail lifts, affects the life of the product? Smooth surfaces are less susceptible to external influences that cause corrosion, and are more wear-resistant. With our roughness measurements, we determine the state of the surface so that you can extend the life of your tail lift if necessary. Find out more here!

Cleanliness test at pumps

Proper maintenance is important! Ever thought that your pump needs to undergo a cleanliness test? Read on to find out how.