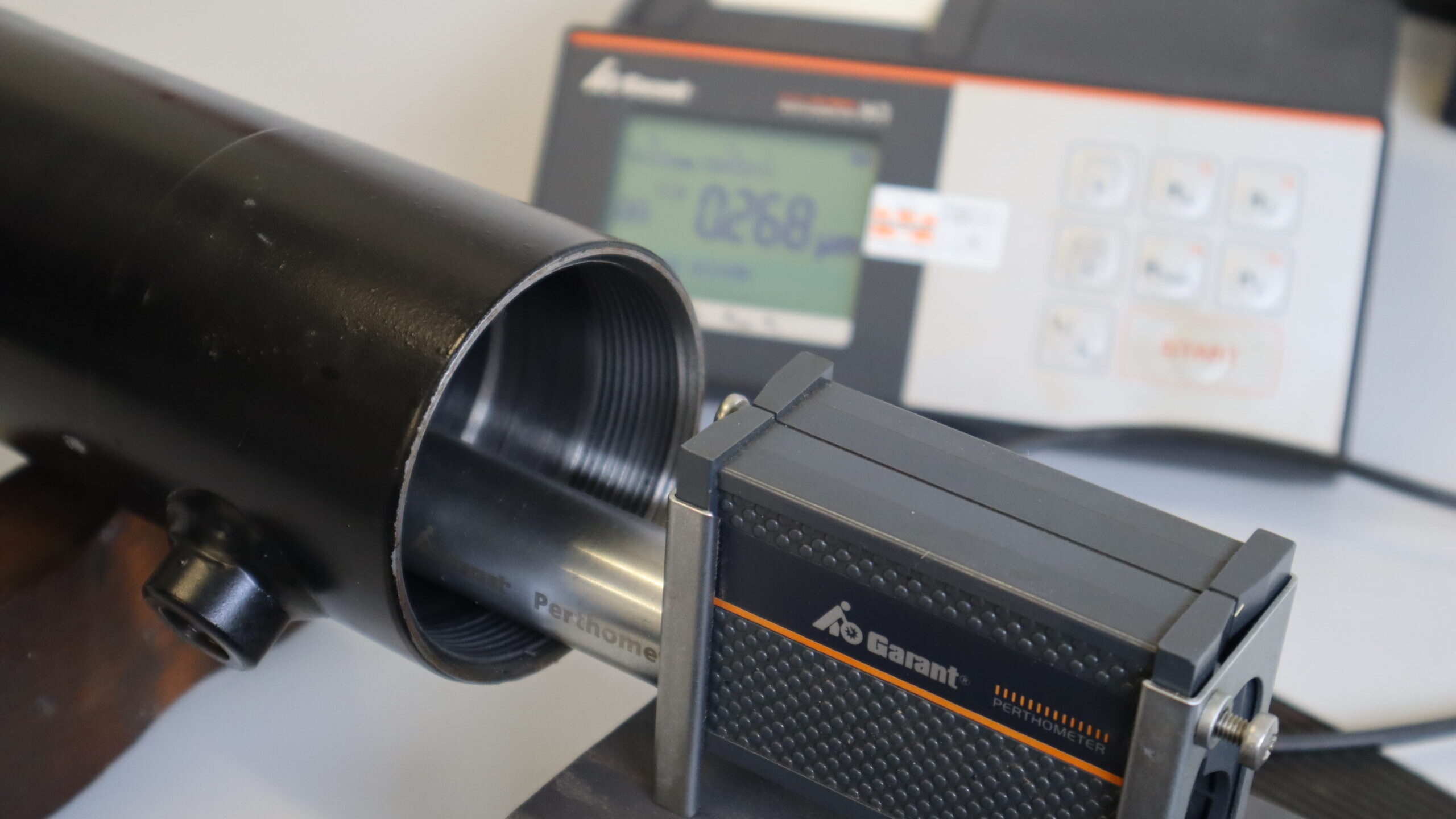

Roughness measurement

Optimize the life of your tailgate components with roughness measurements

Have you ever considered that the roughness of a surface, such as in tail lift components, affects the product’s lifespan? A smooth surface is better suited to withstand external influences that can cause corrosion and offers a higher degree of wear resistance. With roughness measurement, we assess the quality of the surface. The outcome of this measurement allows us to ensure the longevity of your tail lift. Discover here how this process works!

Roughness measurement in tail lifts

At HACO Tail Lift Parts, roughness measurements are conducted using advanced roughness meters. With these, we can analyze the surface condition in terms of roughness. Specific roughness values apply to cylinder tubes and piston rods. If these parts are too rough, seals can wear out and leakage can occur. Regular checks using roughness measurements can prevent such problems.

Related wiki's

Hardness measurement

A smooth workday begins with well-functioning equipment, which not only increases work satisfaction but also enhances efficiency. However, a malfunctioning foot control of a tail lift can cause a lot of frustration. Fortunately, this can easily be prevented through a simple test. In this text, you’ll discover how we avoid such annoyances and make your workday run more smoothly.

Cleanliness test at pumps

Proper maintenance is important! Ever thought that your pump needs to undergo a cleanliness test? Read on to find out how.

What is layer thickness?

Properly functioning machines require top-quality parts, especially if they are constantly exposed to external elements. Layer thickness measurement ensures the quality of chromed surfaces. Find out how it works here!