Periodic check-up/ maintenance

Inspect the tail lift weekly to:

- Checking the identification sticker, safety stickers, and other safety features (center of gravity marking, etc.).

- Ensure that the control switches of the external control and additional control return smoothly to the neutral position.

- Check the covers of the control box and the hydraulic unit; are they still present and undamaged?

- Clean the tail lift. (Note! During the first 6 weeks after installation, the tail lift should not be cleaned with a high-pressure washer because it removes the grease. After cleaning with a high-pressure washer, greasing of all lubrication points is necessary, see lubrication plan.)

Minor service

Inspect the tail lift quartely to:

- Check the hoses and replace them immediately if there are hairline cracks; the cause is often drying out of the external layer.

- Check and replace the filter if necessary.

- Check the wiring.

- Check for oil leaks.

- Check the mechanical parts, play in pins and bushings.

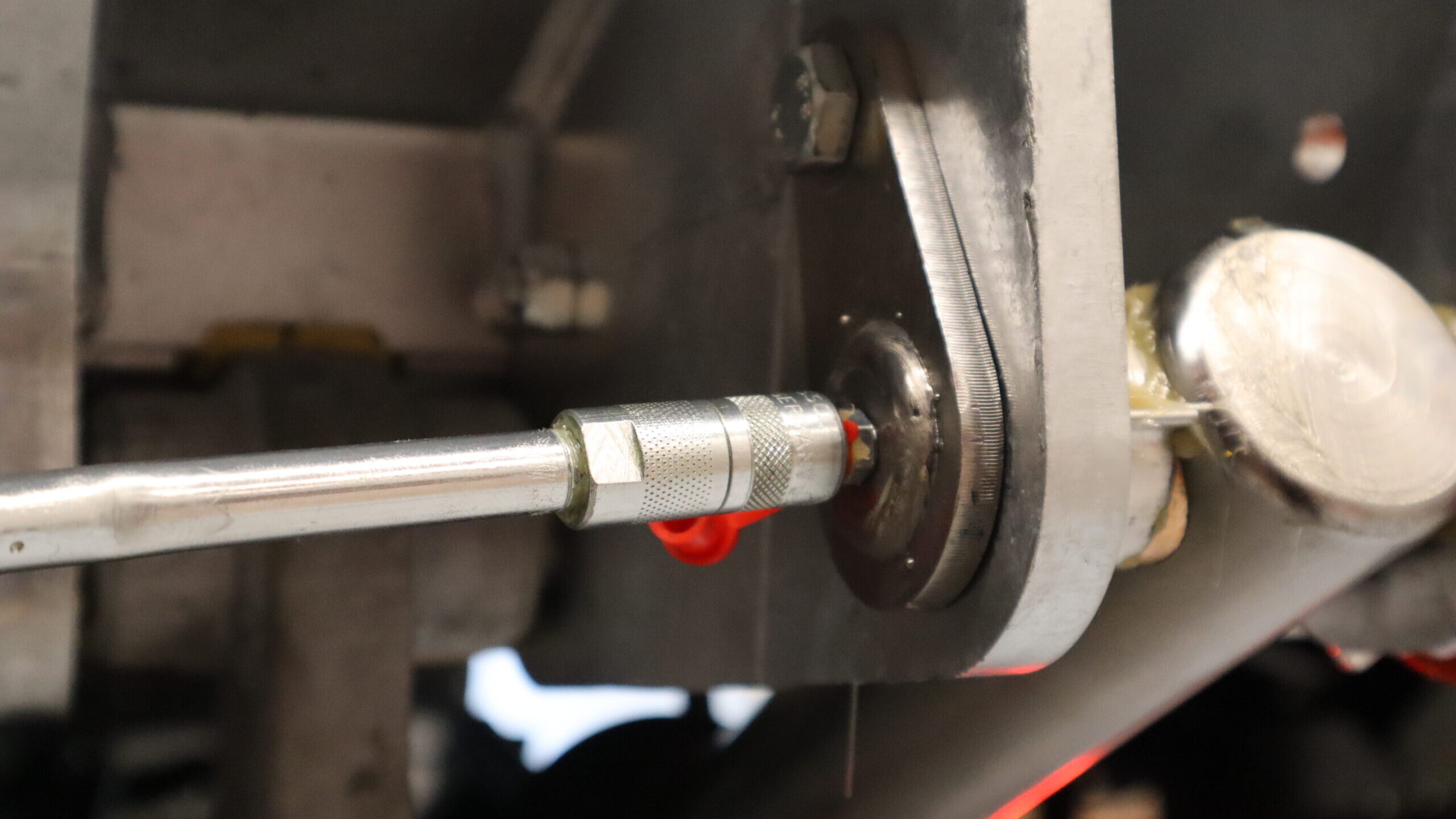

- Clean and lubricate the tail lift thoroughly.

Major service

Inspect the tail lift annually to:

- Change the oil and flush the hydraulic system.

- Check the hoses for drying out and small hairline cracks; replace them immediately if deviations are found.

- Replace the oil filters.

- Check the electrical system such as wiring, batteries, fuses, and contact points.

- Check the mechanical system (play in pins and bushings). Thoroughly lubricate the tail lift after cleaning.

Related wiki's

LPK Inspection

In the Netherlands, the tail lift must be inspected at least once a year. This can be done through the LPK Certification (Tail Lift Periodic Inspection). Thanks to this certification, the safety of your tail lift is better ensured. For expert LPK inspections, you can turn to companies affiliated with the LPK certification, and you can also inquire about this per country when your tail lift needs to be inspected.