Lubrication plan checklist

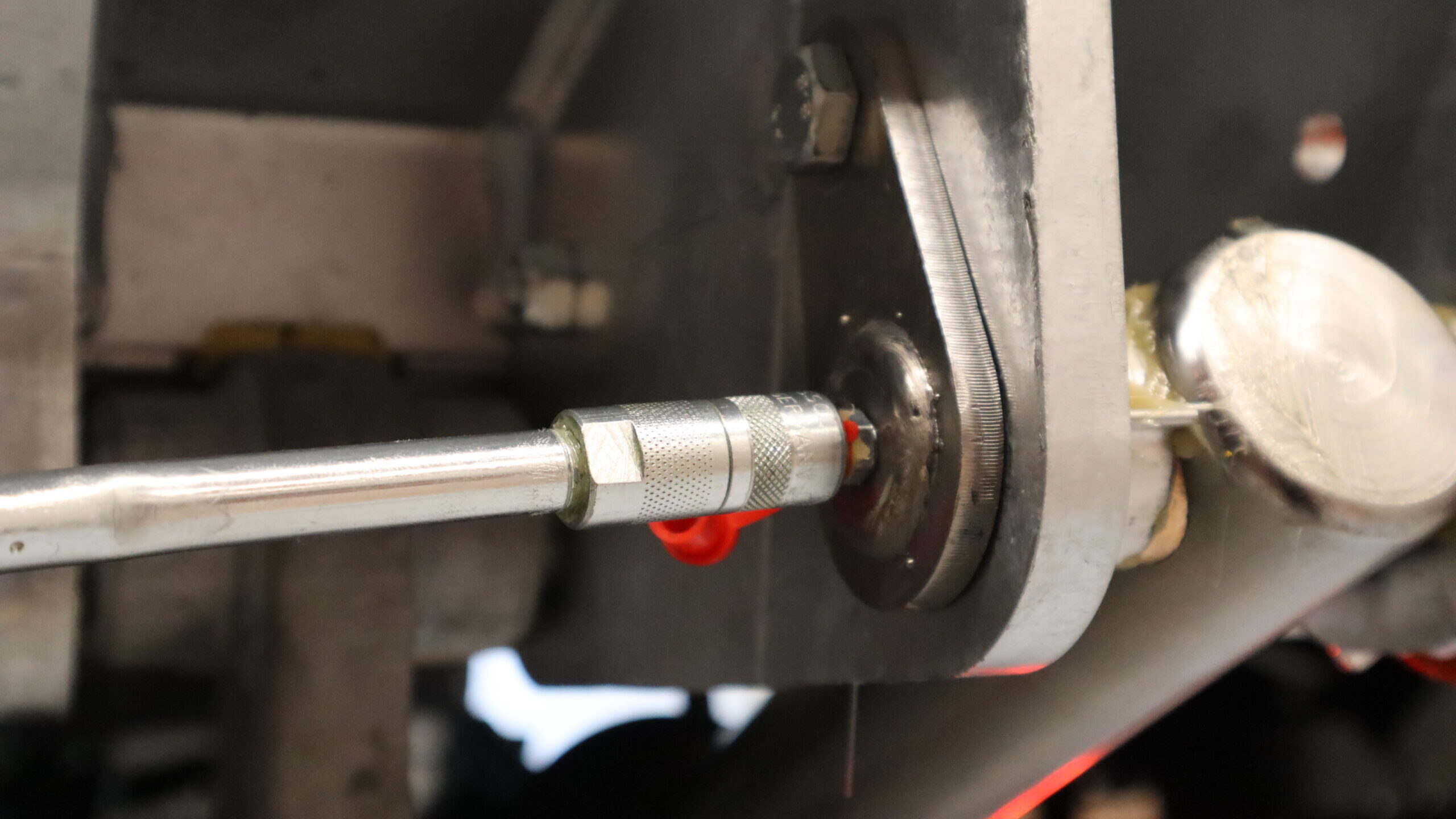

The grease fittings (grease nipples) are located at the ends of the pins at all hinge points.

- First, thoroughly clean the tail lift to ensure that the grease fittings (grease nipples) are clean

- All hinge points should be equipped with a grease collar, which protects them against sand and salt. A grease collar is a layer of lubricating grease

- Before greasing, lower the platform to the ground so that the hinge points are free of load.

- Check that all grease fittings (grease nipples) are effectively supplying grease to the outer collar of the hinge bearings and replace any defective grease fittings

- Ensure that all pipes and connections of the nipples are in good condition and are receiving sufficient lubrication in an automatic central lubrication system

- In the case of sliding tail lifts, the sliding system with rectangular tubes should not be greased. The sliding parts with round sliding pieces should be greased over the entire inner surface with grease. It is recommended to do this four times a year under normal use

- Always use acid-free grease

- • Check the closure of the platform

Related wiki's

Get your tail lift ready for the winter!❄️

With these simple tips, you can effortlessly keep your tail lift in top condition.

Keep your tail lift in top condition with these 3 tips! 🚛✨

3 tips to keep your tail lift in top condition. Read on and get the most out of your tail lift! ✅