Basic structures of the tail lift

Types of lifting mechanisms

Loading platforms are equipped with two types of lifting mechanisms:

- The parallel lifting mechanism

- The column lifting mechanism

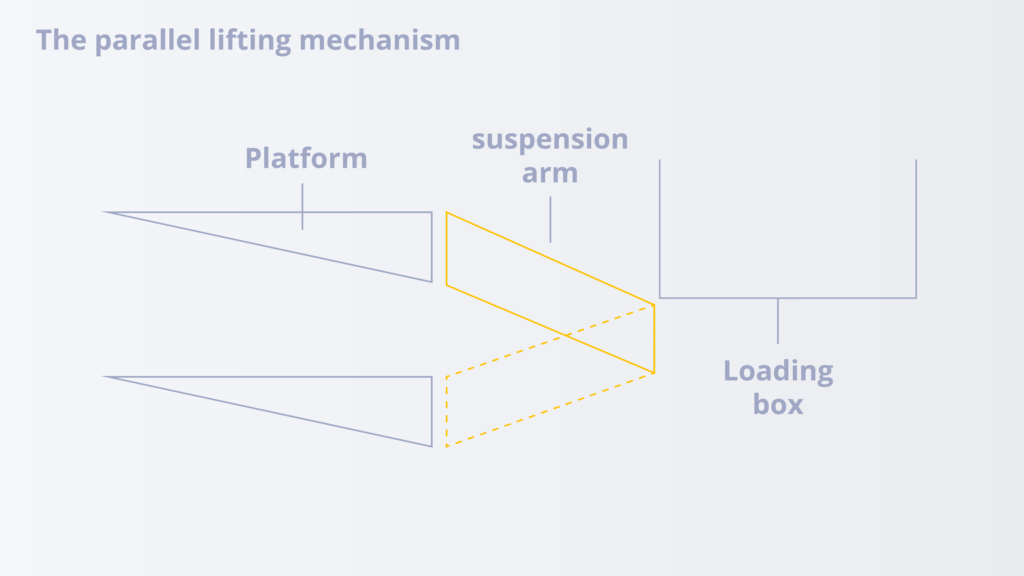

The parallel lifting mechanism

This construction is based on the principle of the parallelogram. Lifting and lowering are fully hydraulic. Within this category, there are cantilevers and under-sliders.

Cantilevers close behind the truck and cover the loading area largely. A hydraulic lifting cylinder operates the platform for up and down movements, while a closing cylinder opens and closes the platform, sometimes also tilting.

The under-sliders, which hangs under the loading box, is designed for flexible loading and unloading. It can be extended when needed but remains retracted when using a loading dock. Loading/unloading can then be done, for example, using a forklift

The under-sliders loader hangs in rails, usually sliding tubes, and can be fully retracted using sliding blocks, rollers, or a combination thereof. Due to the limited free length, the platform is folded in two. The two platform parts are called the head and tip sections. Folding is done manually, sometimes with the help of a torsion spring. Or hydraulically, for example, by a folding cylinder.

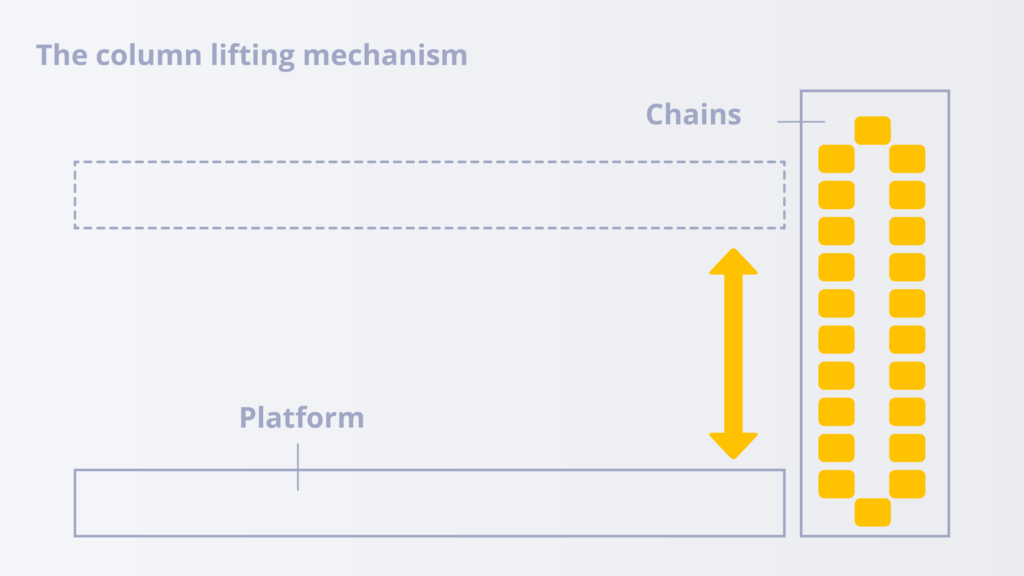

The column lifting mechanism

It uses a simpler mechanism. Lifting and lowering are done hydraulically using a cylinder and chains or cables in the gantry. Thanks to the symmetrical drive system of the platform, guided by the frame in which the chains run, there is minimal movement and vibration. An important advantage is precise positioning at different levels, which is particularly useful for loading and unloading cars, livestock, or moving vans.

Related wiki's

Sliding cylinder drive

Learn how the double-acting sliding cylinder functions to efficiently slide the tail lift in and out, despite the challenges of its mounting location under the tail lift.

Drive with a hydro motor

Discover how hydraulic motors enhance the efficiency and control of tail lift drives through direct power transmission and minimal space requirements. Learn more about their integration with gears and hydraulic systems for smooth operation.

Tilt, up and down tilt

Discover the three different methods to effectively manage tail lift skew. Each system has its own features and applications. Read far