Electric drive

Electric

An electric drive converts electrical energy into mechanical energy, enabling machine parts to be set in motion. The significant advantage of electric motors is that they can be connected to the electrical grid, and machines powered by electricity can be equipped with a battery. In the case of tail lifts, an electric motor is used to drive the hydraulic pump.

Electric control

Electric components are operated by switching elements.

Switching elements regulate the power supply:

- NO- normaly open, contact elements do not allow current to pass when unoperated

- NC- normaly closed, contact elements allow current to pass when unoperated

Switching elements operate:

- The main power relay

- The hydraulic valves

- The control relays

Switching elements electronically control tail lift components.

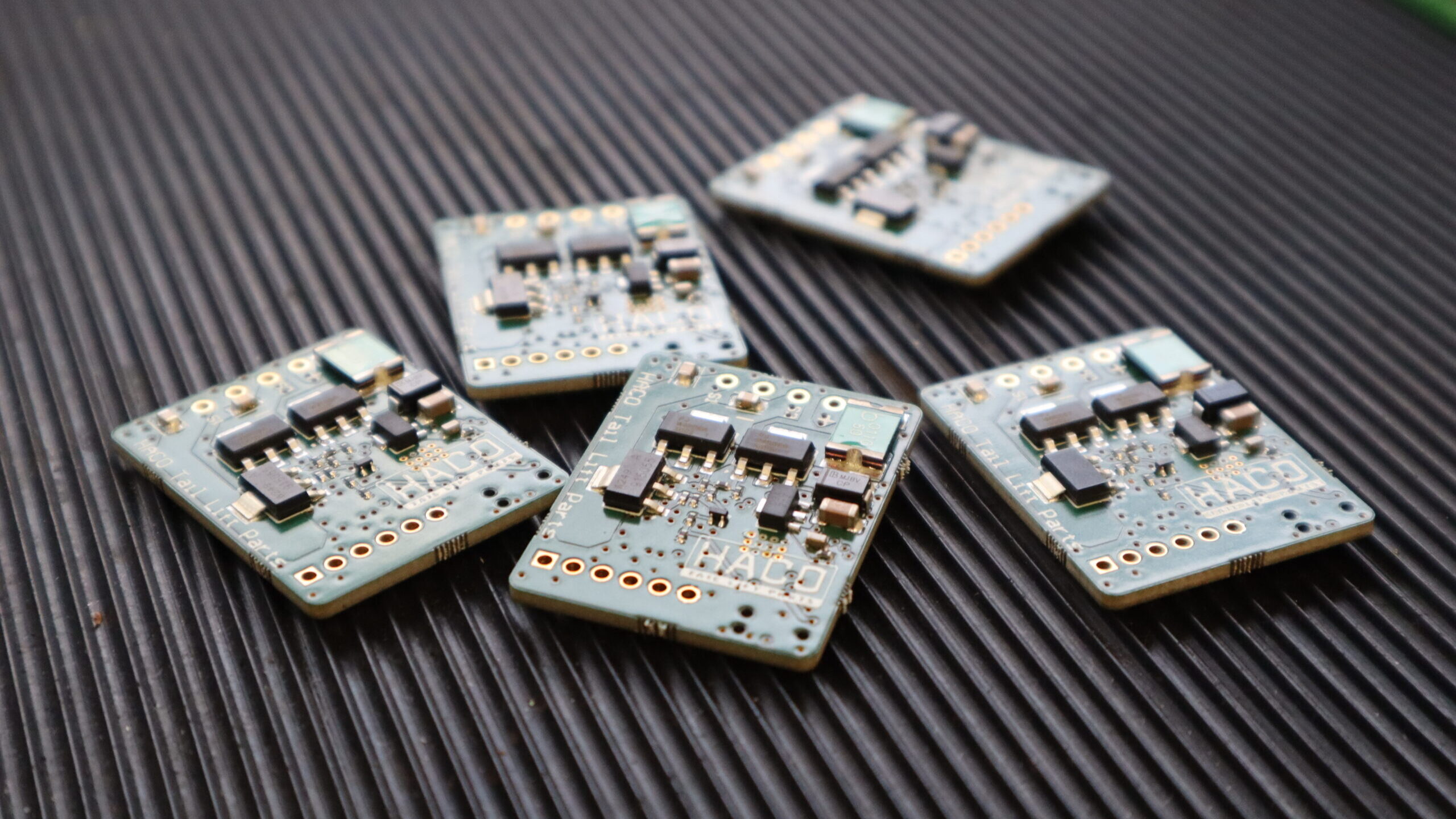

Electric parts

An electric drive converts electrical energy into mechanical energy, allowing parts of tools to be set in motion. Under the HACO brand label, Haco Tail Lift Parts sells electric parts that are fully interchangeable with electric parts of all tail lift brands. These include: battery terminals, battery cables, control panels, proximity switches, interior controls, cabin switches, rotary pushbuttons, limit switches, electric motors, manual controls, main power switches, joysticks, cable harnesses, costal cables, indicator lamps, flasher relays, mercury switches, mini relays, printed circuit boards, switching elements, spiral cables, plugs, trailer cables, rocker switches, foot controls, fuses, fuse holders.

Mercury switch

Due to the ban on mercury, these switches are increasingly being replaced with angle sensors.

Electric motor

An electric motor converts electrical energy into mechanical motion. This happens when the coils are placed in a magnetic field. When the coils are electrically charged, an electromagnetic field is created. This field causes the rotor to rotate slightly as the charge is attracted or repelled in the magnetic field

Maintenance of electric parts

- Visually inspect the motor for damage.

- Check the plug connections and cable lugs in the unit for corrosion and proper clamping.

- Check the main power wiring for wear spots, cable eye connections, fuse corrosion, and corrosion of the battery pole clamps.

- Check the voltage to the motor and the current consumption.

- Listen for any irregularities during motor rotation (the bearings).