Mechanical drive

Mechanical transmission is a method in which motion and force are transferred through mechanical components, known as transmission. The purpose of transmission is to convert force into speed and speed into force at the right time.

Tail lifts often use drive motors, usually hydraulic motors. Hydraulic motors have specific speed and torque (Nm). Since the speed at which tools operate varies, transmission systems are used to control the correct speed, power, or torque. These systems are also known as transmissions.

Mechanical drive

Mechanical transmissions are widely used in engineering and are also among the oldest forms of transmissions in technology. Over time, various mechanical systems have been developed to transfer forces.

The following transmissions are part of mechanical transmissions:

- Gear transmissions

- Worm gear transmissions

- Belt transmissions

- Chain transmissions

- Cardan transmissions

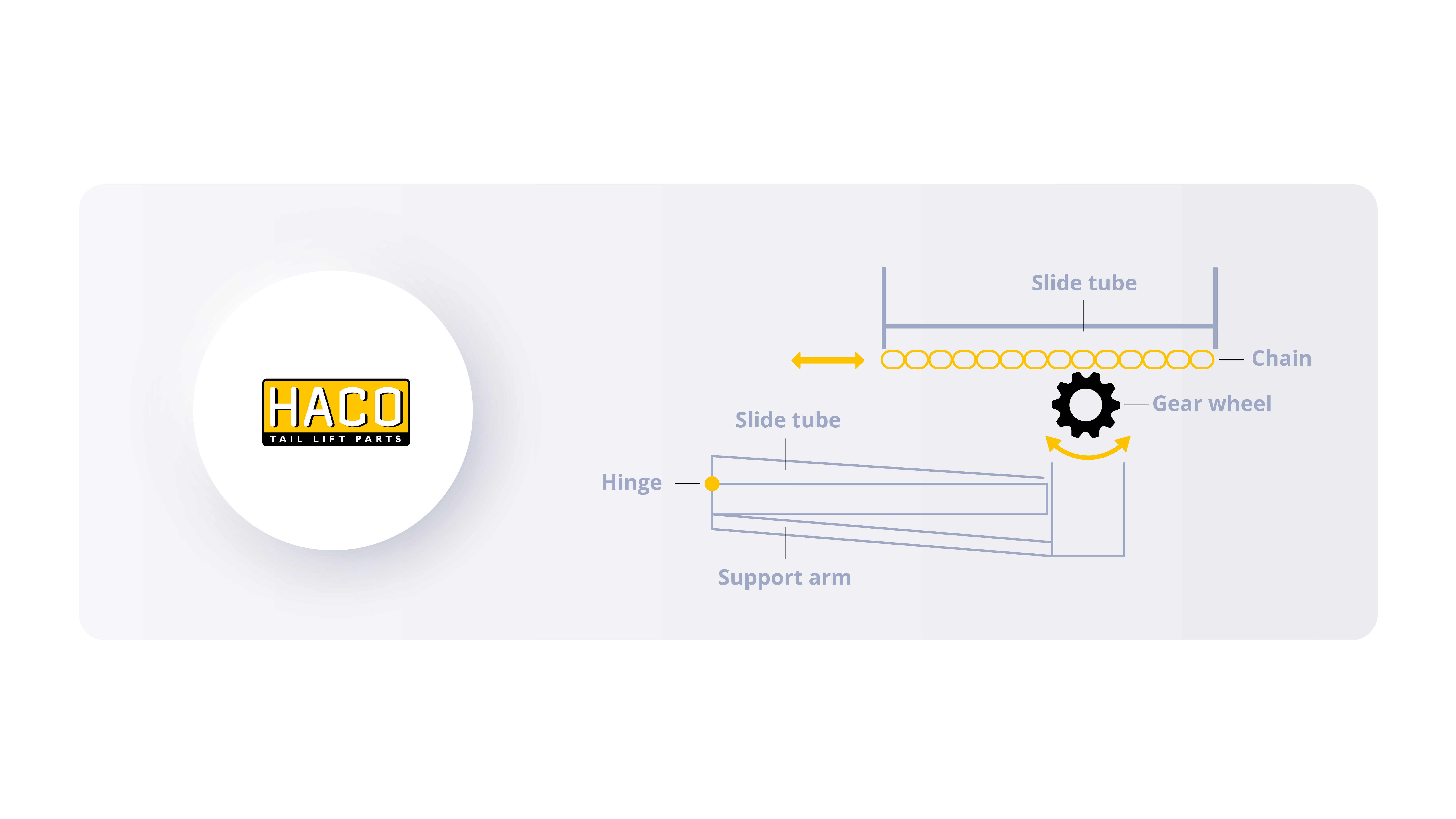

In tail lifts, mechanical transmission is mainly seen in undersliding tail lifts. Here, the extension and retraction of the tail lift are activated by means of a chain (see Fig.)

Mechanical parts

A tool requires specific speeds, forces, or torques that may differ from those of the drive motor. Therefore, a (variable or non-variable) transmission is needed between the drive motor and the tool, which is achieved through mechanical parts.

Under our own brand HACO, Haco Tail Lift Parts offers mechanical parts that are fully interchangeable with the mechanical parts of all brands of tail lifts. Examples of these include:

pins, bushings, platform rollers, roll-off guards, bumper parts, caps, gas springs, slide bushings/strips, sliding parts, sliding tubes, platform parts, platform locks, swing pieces, fenders and springs.

Maintenance of mechanical parts

- Check pins and bushings for play and locking, lubricate them and spray plastic parts with a protective spray.

- Check swing pieces for bending and cracks, keep them greasy by lubricating them well, also after each wash.

- Assess the suspension for cracks and lubricate the gears, also rack/tooth bar and chain.

- Check the main tube for (extreme) torsion.

- Check folding platform hinges for wear and adjustment.

- Assess proper operation of all valve movements (speeds, coming straight to the load floor, closing straight, etc.).

Related wiki's

Electric drive

An electric drive converts electrical energy into mechanical energy, causing machine parts to move. Electric motors can be connected to the power grid or powered by a battery, offering flexibility. For tail lifts, an electric motor is used to drive the hydraulic pump.

Hydraulic drive

A hydraulic actuator uses fluid pressure to generate movement. This is applicable for various loading valves.